Circular Technologies is proud to be an industry leader when it comes to urethane roller manufacturing. Since 1973, our company has expanded and grown while always finding new ways to outdo ourselves in terms of quality and efficiency. If you’re looking for a urethane roller source for a variety of applications, let our team of experts help.

Talk to our team today to learn about our various urethane roller options and let us help you identify which options are best suited for your needs.

High-Quality Urethane Rollers

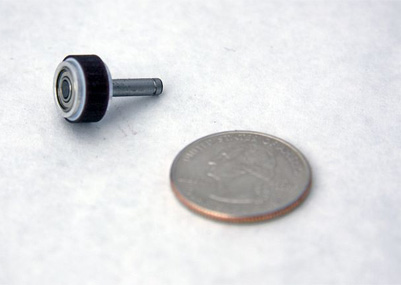

Our rollers are manufactured using polyurethane material which offers longevity in the form of the sustained coefficient of friction (COF) and wear resistance. They also have the added benefit of mitigating noise, which is ideal in data library, front office, and residential environments.

What sets our urethane rollers apart is durability and unmatched precision. Controlling both diameter and runout dimensions are critical when running at speeds of 200 inches per second. In that kind of environment, there is no room for variation on a single tire or across multiple rollers. Our urethane rollers effortlessly handle the demands placed on them. Even if your application is less rigorous, we give the same detailed attention to molding and grinding every roller.

We work with a range of diameter sizes up to 2.0”, so don’t hesitate to reach out to Circular Technologies about our urethane roller products. We’ll work with you to get you the rollers you need that will meet your performance requirements.

Browse our gallery below or select from the listed categories to find the parts you need. And, if you have any other questions about our products we’d love to hear from you at (800) 215-1831.